Permeable Concrete

HEAT ISLAND, A THREAT TO OUR HUMANITY

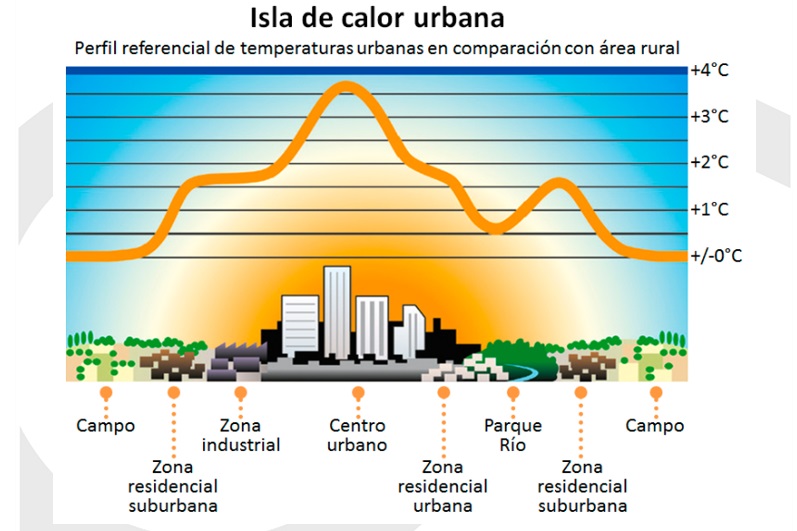

We can define the term “Heat Island” as describing built areas that have higher average temperatures than the open countryside that surrounds them.

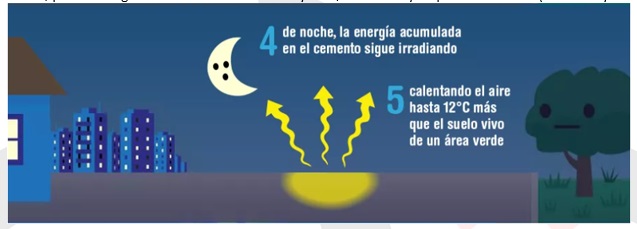

A new environmental phenomenon known as the “Urban Heat Islands” effect is another major concern in urban areas, caused by solar radiation that, when absorbed by impermeable pavements such as asphalt and hydraulic concrete, radiates heat and generates heat gain. of the ambient temperature, other influencing factors are:

- The density of buildings, vehicle emissions.

- The lack of green spaces, the materials used in the construction of waterproof pavements such as hydraulic concrete and dark-colored pavements such as asphalt, which in addition to being waterproof is highly polluting.

Asphalt, like any dark surface, absorbs solar radiation to a greater degree and radiates more heat to the environment, increases its temperature, modifies microclimates and affects global warming, with the consequent climatic changes throughout the planet, to the detriment of the environment, natural resources and quality of life.

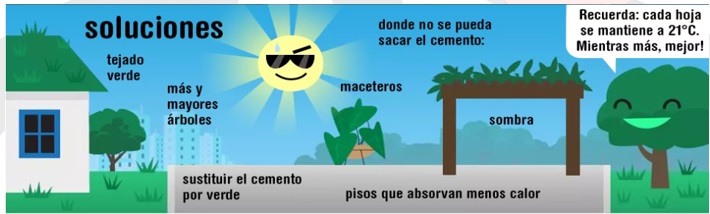

The so-called “Urban Heat Islands” effect can be reduced with alternative design, construction and material practices, which is easily achieved by building pavements with cutting-edge technology that helps improve the ecology, environment and quality of life, such as This is the case of permeable concrete pavements.

Light surfaces reflect and disperse solar radiation, concrete pavements reflect up to 2.8 times more light than asphalt pavements, resulting in significantly cooler surface temperatures, even on the sunniest days, in addition to the high reflectivity of concrete. translates into savings in energy consumption, since lighter pavements require less lighting at night and lower temperatures mean less use of air conditioning.

Pervious concrete, with its light weight and color characteristics, stores less heat than conventional concrete or asphalt, which helps reduce the Heat Island Effect. Additionally, the gaps allow water stored in the soil to evaporate in warm weather, preventing an increase in temperature.

Solar reflectance, also called albedo, is the percentage of solar energy reflected by a surface. Typically, for concrete it is between 35% and 40%, being higher than that of asphalt (between 5% and 10%).

The options to counteract the effect called “Urban Heat Islands” are:

-

- The paving of the new roads with permeable ecological concrete.

- The replacement of damaged asphalt or waterproof hydraulic concrete pavements with permeable ecological concrete pavement.

- The coating of damaged pavements with asphalt or waterproof hydraulic concrete, placing an overlay of permeable ecological concrete.

- Roofs and floors with highly reflective surfaces (“cool colors”, “cool roof”).

- Architectural designs that generate shady spaces as a prevention of thermal stress due to heat in humans, for example, arcades and galleries.

- Increase and optimization of green areas with permeable paths to help incorporate water into the ecosystem.

- Installation of green roofs and facades.

The result, cooler communities, savings in the use of electricity, improvement of the environment and quality of life.

The authorities responsible for urban development and public works must be aware of the deterioration caused to the environment by continuing with the same practices of waterproofing urban areas when using materials such as asphalt and hydraulic concrete for paving vehicular or pedestrian roads. , materials that prevent the filtration of rainwater, losing the opportunity to recharge the aquifers, in addition to generating the effect of “Urban Heat Islands” in the populations.

So, the quality of life in our cities is in the hands of urban planners, investors, architects and builders, and particularly in the hands of politicians.

DELIVERING QUALITY BUILDING EXPERIENCES IS OUR PROMISE

OUR VALUES CONTINUE TO SET US APART.

INTEGRITY

We believe that being ethical in all we do inspires trust. We say what we mean, matching our behaviors to our words and taking responsibility for our actions.

HONESTY

We believe that honesty is doing the right thing under all circumstances. Honesty is central to our business and in our commitment to our clients, contractors, and colleagues.

TEAMWORK

We believe the best solutions come from working together.

CUSTOMER EXPERIENCE

We believe when we bring our knowledge, proven experience and reliability to our work, we create a customer experience with outstanding results.

QUALITY

We insist on bringing value to our customers by our high standards through our suppliers and employees. We are committed to continual innovation and we are proud to get it right.

COMMUNICATION

We believe that clear communication is the only way to do business. We are committed to timely and direct communication to ensure the appropriate responsiveness.

Overall, we believe in our promise: To offer a new home building experience that is uncommon among most builders today. To provide complete support and expertise throughout the entire building process. To be reliable, accessible and responsive. To provide a level of professionalism that will help make your dream home a beautiful reality.

Discover

Construction Garita & Associates

Pervious (or porous) concrete is basically a mixture of cement, water and coarse aggregate. Sometimes a content of fine aggregate and additives is included in the mixture in order to improve its properties in the fresh and hardened state or it is eliminated altogether, which contributes to creating empty spaces around the coarse aggregates. The strength and permeability of porous concrete are its most important properties. These properties must be balanced to achieve adequate material performance. It is a concrete that allows rainwater to be filtered instead of using expensive storm drainage, which reduces the thickness of stormwater pipes, drains and wells.

Contact Roger at +506-8386-3928 to learn more!

Construction Garita & Associates

Contact us to help build your dream

U.S. Number: (913) 407-6594

C.R. Number: +506-8386-3928